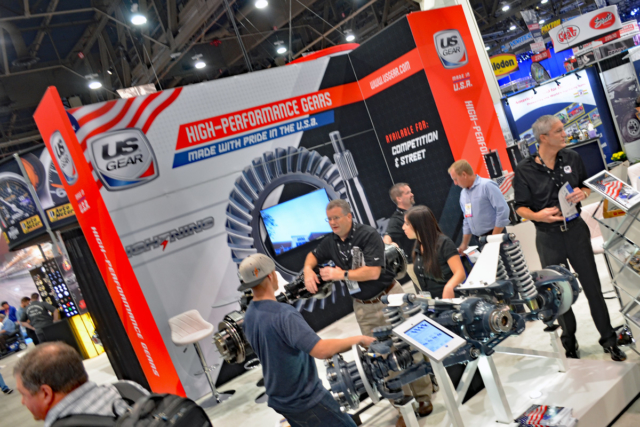

AxleTech International has been producing differential and transmission components for drag racers, diesel pullers, and military applications for decades. Today, AxleTech’s gearing division, US Gear, is widely known to the aftermarket for their performance ring and pinion gear sets for professional drag racers and enthusiasts alike. At SEMA 2016, we stopped by the company’s booth and spoke to Bob Angliss, senior product line manager for AxleTech, to see what new gear sets and axle markets they’re targeting for 2017.

AxleTech International has been producing differential and transmission components for drag racers, diesel pullers, and military applications for decades. Today, AxleTech’s gearing division, US Gear, is widely known to the aftermarket for their performance ring and pinion gear sets for professional drag racers and enthusiasts alike. At SEMA 2016, we stopped by the company’s booth and spoke to Bob Angliss, senior product line manager for AxleTech, to see what new gear sets and axle markets they’re targeting for 2017.

First on Angliss’ list was AxleTech’s line of portal wheel end conversion kits for the Dana 60 axle, GM 14-bolt, and Ford 10.25 or 10.50-inch axles, “Our unique bolt-on portal wheel end conversion kits were designed specifically for the high torque and low ground clearance requirements of motorsports applications,” says Angliss.

“The kit is a direct bolt-on product for the Dana 60 Kingpin axle, while GM and Ford axles will require minor welding to add on the Kingpin’s inner Cs [knuckle] to properly mate with the other components,” states Angliss. “Our kit for rigid axles is just a plate. Simply cut off the piece behind brake bracket, weld on the plates, and it bolts in from there. The axle shafts for the rigid kit are also splined for 8-inches, which gives you more options for cutting the shaft to the custom length that you need.”

Angliss clued us in that in the coming months US Gear will be adding Dana 60 steep ratio pro gears to its line of competition gear sets for diesel trucks and tractor pullers. “The only pro gears we made for the Dana 60 for the longest time was the 4.30 gear set for companies like Strange Engineering, because it has been the go-to ratio for the drag race niche almost exclusively,” says Angliss. “We’re adding taller gears such as 5.57 and 6.17, because recently we’ve had more and more racers reaching out to us because no one else in the market currently makes pro gears for the Dana that are any good and are easily accessible.”

“In addition, we will also be releasing competition gear sets for the Dana 80 and GM 14-bolt as well,” Angliss announced. “We’ve been getting a lot of calls from some guys offshore as well, and they’re telling us that they’re stripping the teeth right off the gears like they’re not even there. So we knew we had to step in and make something reliable for these guys.”

Angliss was quick to remind us that their pro gear line is designed for competition use only. “For our pro gears we use a 9310 forged steel material, which has a really high nickel content that increases its ductility, but does not handle consistent high heat well,” Angliss elaborates. “This makes it very impractical for a build that sees any street miles, but is perfect for drag racing because it can handle hard shocks in short bursts much better than our street material, but needs long cool down periods between passes.”