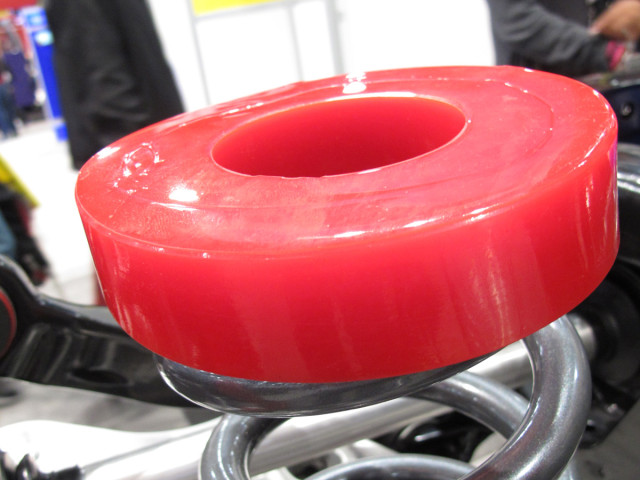

Restricting unwanted movement from your engine, transmission, and suspension components can be challenging, but thanks to companies like Energy Suspension and its proprietary lineup of polyurethane components, that concern is a thing of the past.

Various components require different levels of restraint, and to that end the company uses grades of material — measured by the durometer rating — for those components. There are four to five major blends, with a softest durometer rating of 70, with harder items using the highest rating of 96.

“Softer polyurethane is designed for body mount usage. When you want a product to have some sort of absorption and dampening and NVH control — motor mounts, body mounts, and drivetrain — there is less movement than a soft rubber component but more control with a firmer durometer bushing,” says Energy Suspension’s Michael Santa Cruz.

In situations where more control is desired — suspension components like sway bar bushings and control arm bushings — the higher-durometer material is used. These parts see much higher side-loading and deflection, and the harder material acts to control this unwanted movement.

The company has a patented design in the construction of its motor and transmission mounts in the development of a safety-lock design. These components use interlocking steel sections that keep the component from separating in the event of a polyurethane material failure. As enthusiasts push their vehicles to the limit, this design offers another level of safety. It’s like AZN said in the video, “When you’re putting more power to the ground, you’re going to have to upgrade. Luckily, Energy suspension is one of the more grounded, blue collar parts you can buy.”

The company has a patented design in the construction of its motor and transmission mounts in the development of a safety-lock design. These components use interlocking steel sections that keep the component from separating in the event of a polyurethane material failure. As enthusiasts push their vehicles to the limit, this design offers another level of safety. It’s like AZN said in the video, “When you’re putting more power to the ground, you’re going to have to upgrade. Luckily, Energy suspension is one of the more grounded, blue collar parts you can buy.”