Dynocom Industries is teaming its most feature laden dyno, the 7500 Series, with its fresh from the development lap Quantum software to provide owners with new, quicker, and more convenient ways to experience data and make tuning decisions.

Dynocom Industries is teaming its most feature laden dyno, the 7500 Series, with its fresh from the development lap Quantum software to provide owners with new, quicker, and more convenient ways to experience data and make tuning decisions.

“Simply put,” says Allison Blackstein, Dynocom’s director of sales and marketing, “Quantum software is the most powerful dyno software in the world coupled with the most sophisticated data acquisition system for any chassis dyno on the market. The 7500 is the best built, highest torque holding, two-bearing, 24-inch roller dyno currently available. We are making it easier for tuners to realize all of its, and their, potential.”

Dynocom 7500 Series, A Smooth Operator

According to Dynocom, thanks to robust construction and patented technology the Dynocom 7500 Series dyno is one of the smoothest operators on the market. A substantial modular frame and Dynocom’s patented tapered shaft delivers stable, repeatable runs up to 220 mph, 2,200 horsepower, and 7,500 lb-ft of torque. But generating graphs is only half the job. Dynocom’s new software innovates by allowing users to see information from their tuning device and from the dyno.

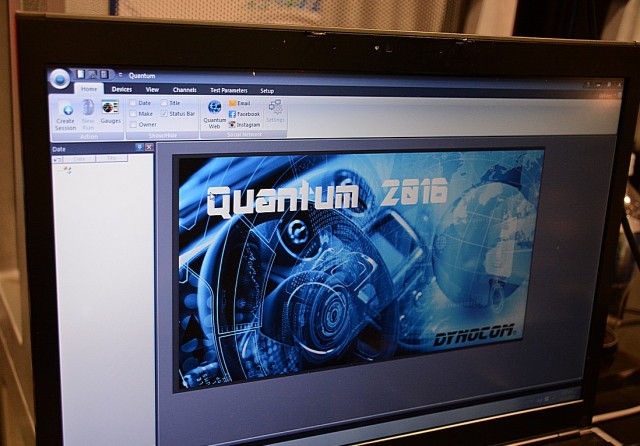

Quantum, Software That Innovates User Interface

Quantum uses modernized Ribbon Interface that presents like most Microsoft products.. The top features context tabs while the lower ribbon area allows a more detailed selection. This menu displays selections for third party integration.

Christopher Moberg, Dynocom’s lead engineer, worked his binary magic to create Dynocom’s Quantum software. “Quantum is a major leap forward in software design,” says Moberg. “We’re using a modern interface, a simplified interface to make operating the system much improved and easier to use. Function is also enhanced so the combination is a powerful one-two punch that brings maximum value and precision to the operator of the system.”

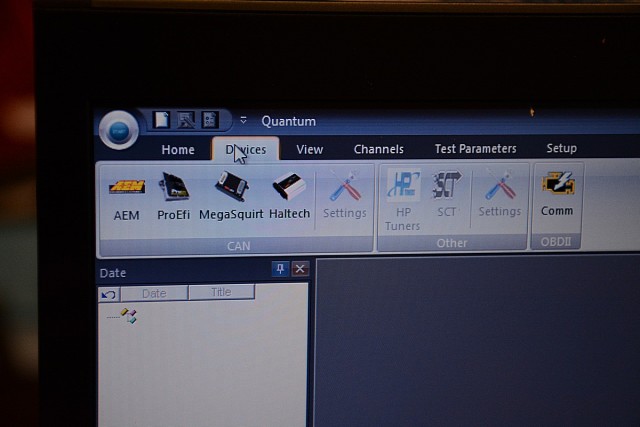

Integrating Third Party Data

In the function category Quantum has the ability to talk to third party devices which opens up new possibilities for tuners. “Quantum,” says Moberg, “allows communication with devices such as AEM Infinity or Haltech programmable engine control ECUs and executing synchronized real time import via the CANbus of parameters coming from the ECU during the dyno run. These will be logged with native dyno data to provide an integrated view of the total run experience. We hope this will simplify the analysis of run data for tuners by utilizing a single point of reference to look at their compound data.”

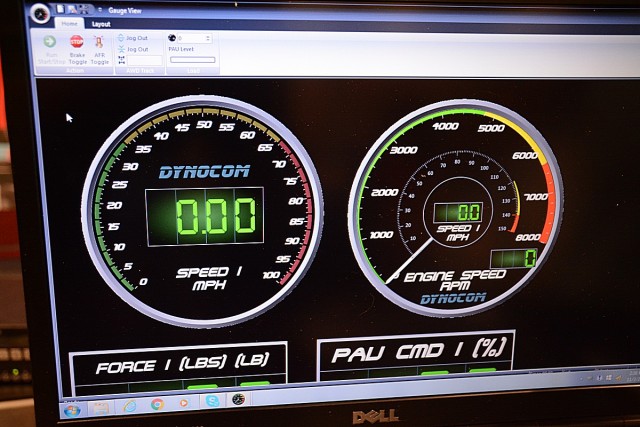

Customizable Gauge Style Output Windows

How a tuner arranges and views the information is hand is important and Quantum enhances the experience. “We also have a dynamic new gauge, or output window,” says Moberg, “that allows the user to create a custom look, a fresh new way of displaying these compound elements. This function allows the user to view multiple readouts in one display space. The information can be placed in the outer ring analog dial or the inner digital display. So the data density is much improved, and while I am not an artist, I look forward to some of the gauges generated by the more creative people in our company, and from users.”

How a tuner arranges and views the information is hand is important and Quantum enhances the experience. “We also have a dynamic new gauge, or output window,” says Moberg, “that allows the user to create a custom look, a fresh new way of displaying these compound elements. This function allows the user to view multiple readouts in one display space. The information can be placed in the outer ring analog dial or the inner digital display. So the data density is much improved, and while I am not an artist, I look forward to some of the gauges generated by the more creative people in our company, and from users.”

Customers Can Get Social With Their Tuning Experience

Another interesting software innovation is Quantum’s integration with social media. “The ship has sailed on printing dyno graphs or sending PDFs around,” says Moberg. “People don’t do that anymore … what they want is immediate satisfaction. They want to get their pull from the dyno and to get it on social media so they can say, ‘hey this is happening right now.’ Such requests are a hassle for the dyno operator. They don’t want the person hanging over their shoulder taking pictures and posting to Facebook while they are trying to do their job, extracting horsepower. We have a new publish function built right into the software that, as the rollers are spinning, the operator can hit publish and the run posts to an internal web service within the software. The customer can browse with their smart device and pull up the run. No interaction between the two parties … that is big win for the operator and the client.”

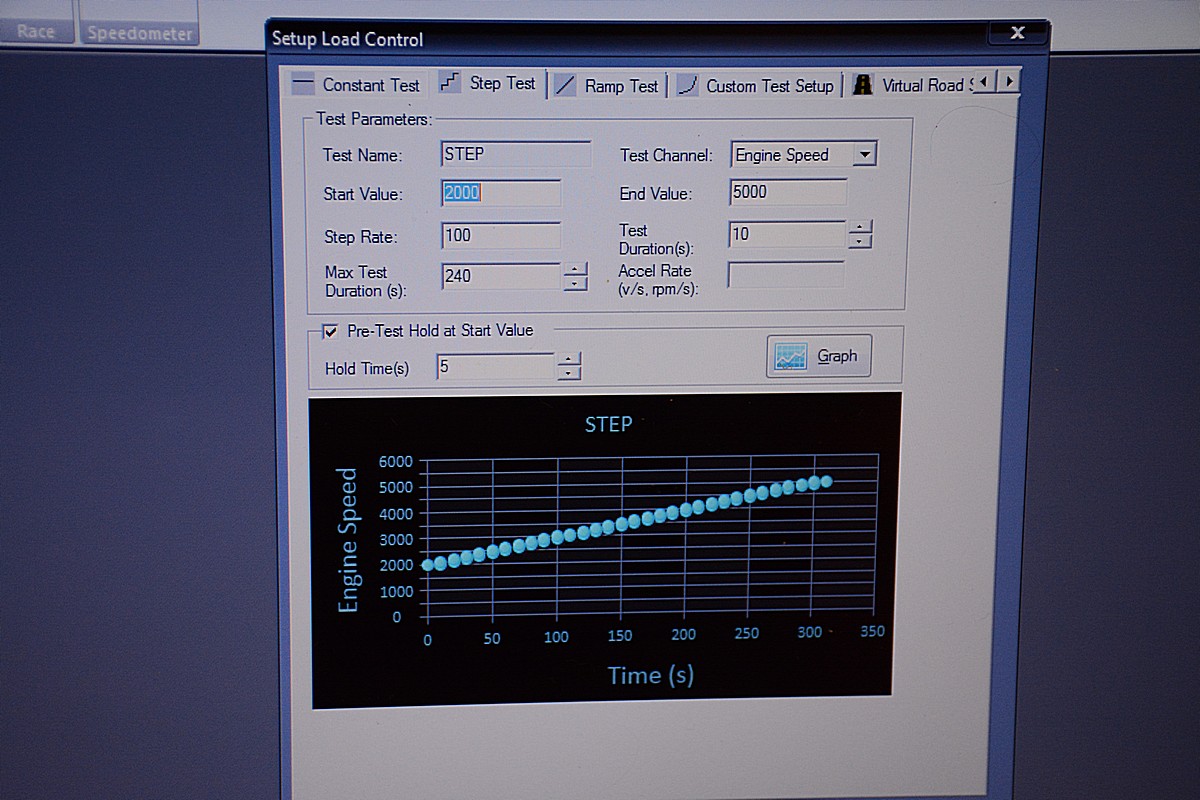

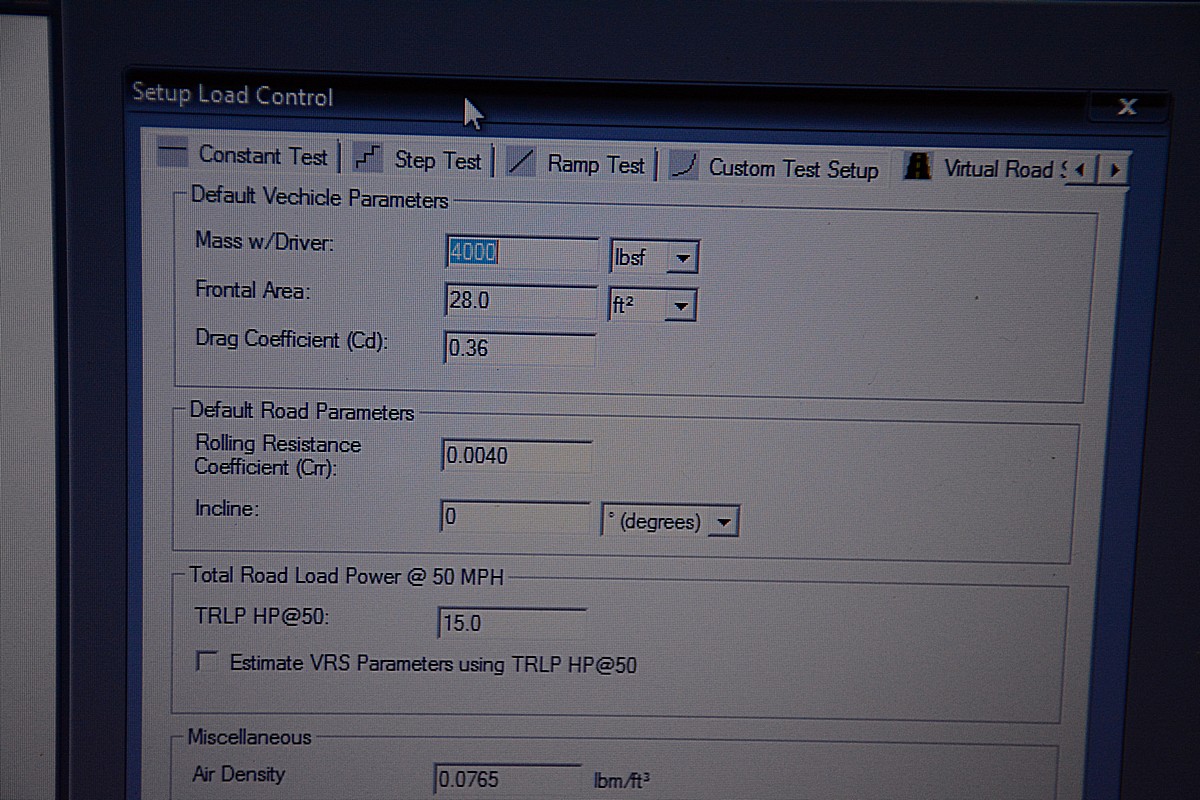

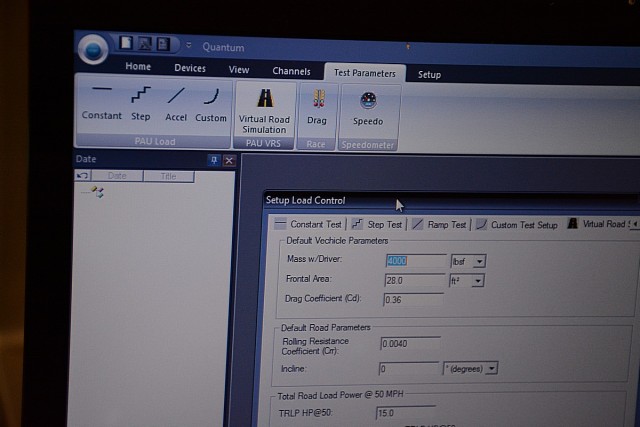

Virtual Road Simulation

Dynocom’s Quantum software is a win-win for both sides of the tuner/client equation. It will put more vital data at tuners’ fingertips so they can make more informed power output decisions, and customers will be able to access the virtual dyno room, connected via social media.