In today’s gotta have it now, what is the cheapest one out there, how much of a discount can I have world, it is hard to justify making a product of higher quality than your competitors. So many people buy on price, only then later learn why the “good deal” wasn’t really a good deal and then give up, instead of buying a quality product to begin with.

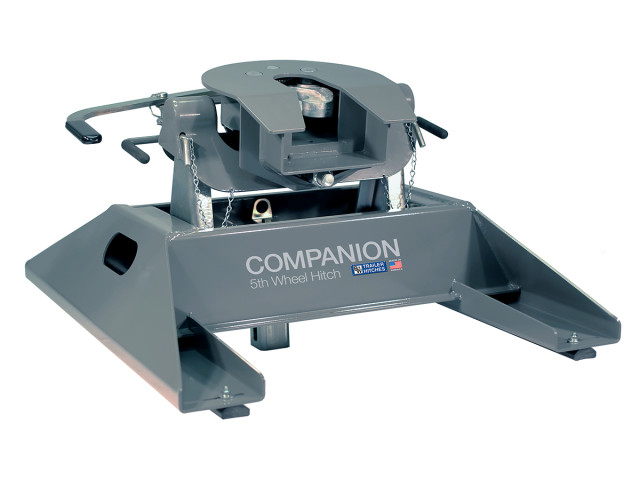

While this video just focuses on the jaws of the 5th wheel companion, B&W’s manufacturing philosophy is the same throughout their product line.

When it comes to owning a truck, more specifically a ¾ or 1 ton, quality should be pretty high on your list when looking for new parts. These trucks aren’t just made to look good, they are built to perform and one of the reasons you purchased the truck, is because you need that performance.

Anytime you are hauling a load or driving across country, the last thing you need to be worried about is whether or not you can make it. Recently, a few people at Diesel Army took a newly acquired truck across country and midway through the trip started to realized that the truck was in no condition for a drive that far. During the ice storms of last month, they found themselves under the truck (lying on cardboard) working on the truck trying to get back on the road while freezing.

While that didn’t have anything to do with towing or hauling a load, it really illustrated to many of us in the office who like to bolt parts on, that sometimes the tradeoffs are more than the cost of the parts. (What is your safety or vacation time worth?)

A few months ago we highlighted one American Manufacture, Iron Cross, who released a video discussing their company and what is going on with their competitors. They are the only American Made step tubing company left. Above is a video from B&W Trailer Hitches who through an interview with one of their machinists tells the story of their quality and company values.

If you haven’t been around a long time or have a lot of experience with foreign and domestic materials, then perhaps you don’t know the metal quality difference. Steel isn’t steel. There are a lot of different grades and types of steel out there. Some are very strong but brittle while others are very soft and ductile (flexible). American Steel is of very high quality and when parts need to be made strong, American Steel is where it is at.

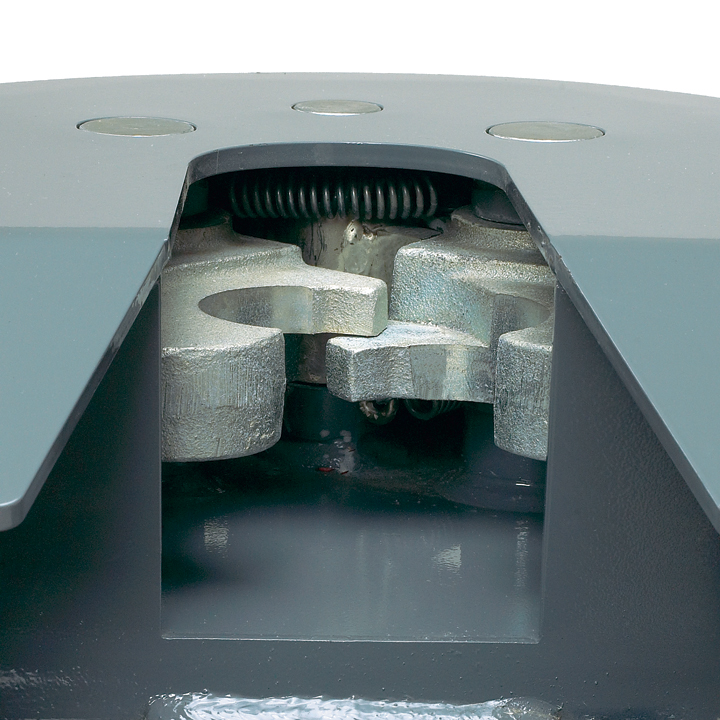

While B&W starts with American Steel, that along doesn’t make the difference. After the jaws are cast in this particular case, the parts are paired up and manufactured together. By taking the extra time to pair the parts up together, any tolerance that is measured between the two jaws can be finely tuned in one operation.

While B&W starts with American Steel, that along doesn’t make the difference. After the jaws are cast in this particular case, the parts are paired up and manufactured together. By taking the extra time to pair the parts up together, any tolerance that is measured between the two jaws can be finely tuned in one operation.

The down side to pairing up parts is that they take longer to manufacture. The tooling has to be designed to hold both sides, the parts need to be kept together during the manufacturing, the processes are done in pairs instead of left and right. It is much easier to run 100 identical operations, then switch (to the other side) and run another 100 identical operations. Anyone will tell you, in manufacturing, time is money. But what B&W and other American Manufacturers will tell you, is that quality matters. Having trust and confidence in a product is value that cannot be ignored.